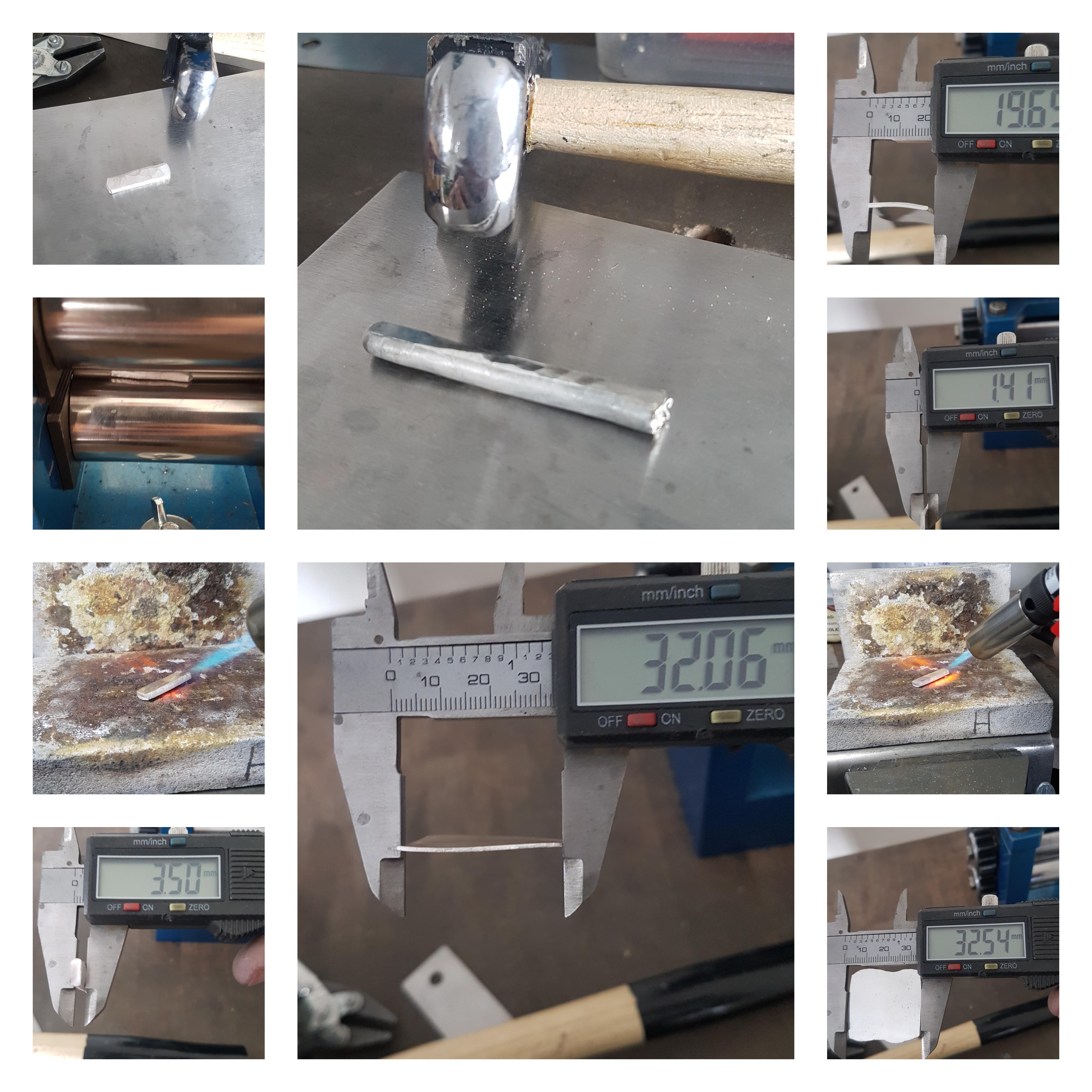

I have been wanting to have a go at making my own silver sheet for ages but not really had the right motivation. A recent custom order for a very special and intricate pendant inspired me to have a go. I was thinking that if I mess up the construction I wouldn't be wasting expensive silver sheet from Cooksons. I always have a decent supply of sterling scrap, cuffs I have miss-stamped, and other bits and pieces. For the sheet, I picked the cleanest scrap I could find and melted it down, and poured it into the ingot mould. I chose the largest mould I have. After a happy and productive morning melting and casting I ended up with a healthy amount of recycled sterling silver ingots.

Next, I took to my steel block, hammers, and my rolling mill. Many passes through the rolling mill and lots of annealing and I had rolled down the metal into a sheet to the 0.80mm thickness I needed. I am limited in size as my rolling mill is pretty basic but the sheet will be big enough for my custom project.

Overall I'm pretty happy with the results, a few tiny bubbles appeared on the surface I'm guessing from some trapped air but these were easily removed during finishing

It feels good to add making sheet to my workshop skills and will be very handy when needed!